Transnational Access Project: Assessment of Inspection tools for Rising mains (AIR)

Institutions involved

- IKT, Germany

- Stichting RIONED, The Netherlands

- Acquaint, The Netherlands

- ROSEN group, Switzerland

- Xylem, France

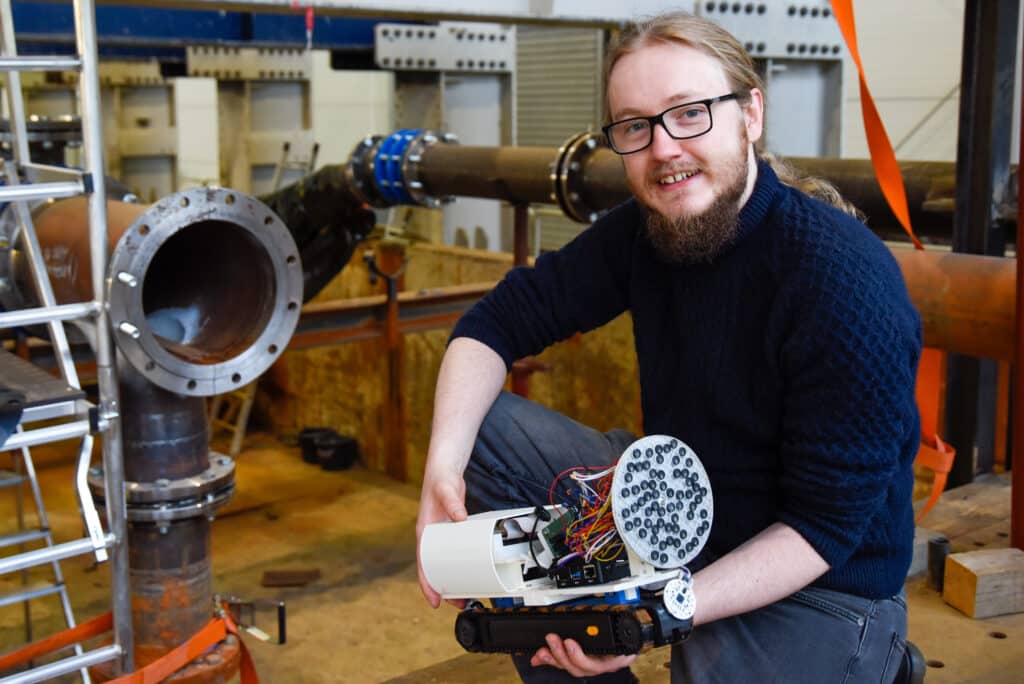

- Pipebots, United Kingdom

- University of Bristol, United Kingdom

- University of Sheffield, United Kingdom

- STOWA (Dutch Foundation for Applied Water Research), The Netherlands

- Waterboard Company Limburg, The Netherlands

- Municipality of Arnhem, The Netherlands

- Waterboard HNK Waterboard HNK

- Wessex Water, United Kingdom

- Severn Trent Water, United Kingdom

- Yorkshire Water, United Kingdom

- United Utilities, United Kingdom

Duration

40 working days in 2023 (8 weeks)

About the project

As part of a Transnational Access project, IKT worked with Stichting RIONED, the TA lead, and a steering group of utilities on the assessment of inspection tools for rising mains (pumped wastewater pipes), also called AIR project. This involved the comparison of methodologies for inspecting pressurised pipes (sewer or surface water pipe) for pumping liquid uphill, which is an area that is not very well understood because pressure sewers were not designed with their inspection in mind. Most pressurised systems are aging, and it is necessary to know the remaining pipe-wall thickness because when they fail suddenly it creates unforeseen pollution and results in a lot of disruption locally.

This project came about as there has been no comparative assessment of available technologies on the market (or soon to be coming to market). A total of 6 technologies were evaluated at the test setup in IKT´s Large Test Facility (IKT LTF). The manufacturers of inspection technologies were invited to be involved in the project to come test their equipment on a pipe with known defects at the KT´s Large Test Facility, with the goal of assessing how accurately the technologies could assess the condition of the pipe and identify the damage, to know if the pipe soon needs replacing. The technologies are either run as tethered devices or flow through the pipe or are within a pipe cleaning pig.

To prepare the facility for the project, the IKT LTF was set up in a new configuration. It was also necessary to design a new length of pipe which was large enough to accommodate the bigger technologies being tested. Then the technology suppliers installed their equipment in the pipe, and used it to collect data, whilst the IKT laboratory engineers managed the hydraulic conditions for the tech suppliers.

Main findings

- The project allowed the development of a methodology for each technology, so that anyone using it can follow the same procedure and have troubleshooting suggestions available to have a swift resolution of predictable issues, should they be encountered in the field. The main challenge was getting the instruments into the pipes, meaning that it’s difficult to install the equipment in the pipes and get the water pressure back up.

- There was a comparative assessment of the 6 technologies tested and their effectiveness at identifying different types of damage or pipe defect was evaluated. There is currently no “magic bullet” to do a comprehensive survey using one technology, it might need a combination of technologies to best survey the pipe in question. However, the data collected allows for more informed decisions to be made as to what technologies, and what combinations of technologies, are most suitable for a given scenario. This can help direct the development of equipment so that in future it is possible to develop one piece of equipment that can do the complete survey.

Successful outcomes:

- The new evidence from the TA project gave enough supporting evidence of the use of these technologies that it was possible to find a new site to run field tests.

- The evaluation of the inspection techniques done during the TA project is relevant for industry in general, as pressurised pipe systems are a common asset for any owner at sites where water needs to be pumped up-hill. By providing data which contributes to understanding the capabilities and the limitations of the leading technologies on offer, the AIR project allows users to decide which option is most suitable for whatever sort of issue they are facing.

- Stichting RIONED will wait until after the field project is complete before widely disseminating results as the field tests bring a high level of credibility to the TA pilot test results. IKT will be promoting the results of the TA in conjunction with Stichting RIONED and has a copy of all the data and reports produced during this TA

- Co-UDlabs, as an EU funded project, requires that no data be permanently withheld. This means that despite the data collected being the property of Stichting RIONED, the data is available to any European researcher with an embargo of a maximum of 2 years after the last test in 2023. This availability of the data helps to overcome barriers to innovation due to commercial interest and allows for dissemination and sharing of the results.

- The technologies tested are commercially available and ready to use.

- Pressure sewer related technologies are a pertinent subject and has lots of opportunities in teh future, so Stichting RIONED will continue collaboration with the TA technology suppliers and with IKT on other projects.

- A future Stichting RIONED field project to test the technologies in a live pressure sewer in Arnhem has been planned as a result of the project.

Useful links:

- Dutch report with a summary in English: https://www.riool.net/producten/professioneel-afvalwatertransport-beoordeling-inspectie-instrumenten-voor-persleidingen-onderzoek-in-testopstelling