Location

Deltares

Delft | The Netherlands

Fields of expertise

Performance of urban assets

Digital water solution

Modality of Access

In-person

Access offered for each project

40 days

Number of Projects

1 (first call)

Expected composition of the visiting user-group

1 researcher during the full access period and 5 researchers for 10 days

Description

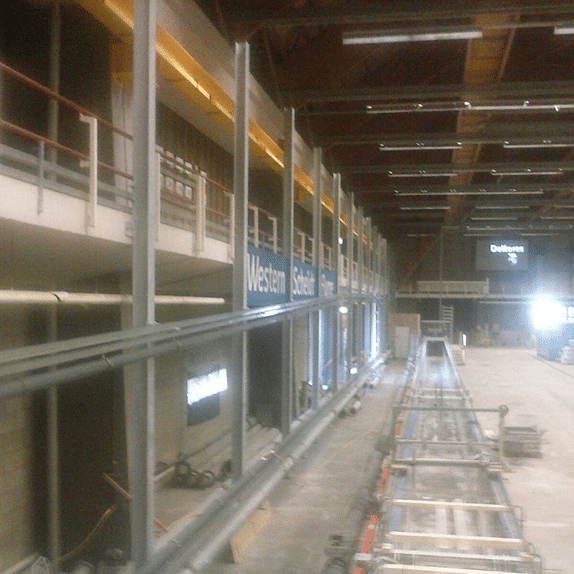

Alpha Loop is a flexible large-scale, multi-phase flow facility to be used for a wide range of academic and industrial research topics considering water, gas, and sediment interactions and transient processes in a pressurized transport network.

The facility consists of a 320 m long pipeline loop (steel PN16 DN200). A part of this loop is connected to a frame (120 m length and 7.5 m height) in order to enable the construction of specific 2D pipe profiles. The facility is equipped with two pumps, each of which supplies a water discharge ranging in between 10 and 200 L/s at a pump head of about 50 m and that can be arranged in series or parallel in order to provide additional head or flow rate capacity.

The air is supplied from a 70 m3 tank (PN16), which is filled by an air compressor with a maximum supply of 3000 m3/h. The facility supports pipe diameters up to 500 mm for assessment of scale effects and transparent sections can be installed for visual inspection of the flow patterns. The system has an array of sensors monitoring conventional variables such as pressure, flowrate (air and water), and temperature.

Service provision

Combined with the measurement expertise at Deltares, this facility provides a unique observation platform for gas, water and sediment interactions and transient phenomena in pressurized transport networks.

The Alpha Loop allows for single-phase (water), two-phase (water, air) and three-phase studies (water, air and sediment) in a pipeline system of a defined geometry.

This has been used previously for a collaborative project with the Dutch water industry consortium to study two-phase flows developed in downward sloping pipes within the scope of CAPWAT project, and to test efficiency of air and particle separation with the participation of a nationwide company. Besides these applications, the test facility can be used for leak detection studies and the generating experimental data for multi-phase simulation software, in particular slug flow models.